Many people are confused about subcontracting. To help those individuals, I am providing relevant ideas about what subcontracting is and how many types of subcontracting procedures exist in Microsoft Dynamics NAV/Navision, etc.

What is Subcontracting?

Subcontracting is a type of work contract that seeks to outsource certain types of work to other companies. This practice is a step down from general contracting, where a contract oversees a broader project. Subcontracting is employed when the general contractor lacks the time or skills to perform certain tasks.

In the construction industry, subcontracting is prevalent, especially when a building is being constructed. While a general contractor may handle tasks such as brick-and-mortar construction, subcontractors are often hired for specialized tasks like plumbing and electrical work.

Larger contractors may handle plumbing and electrical work themselves, but this is rare due to the expertise involved and the desire to focus primarily on one area. If a contractor deals with too many disciplines, it may not clearly focus its efforts on quality in one particular area. In some cases, a general contractor may only serve as the construction manager or supervisor, and subcontracting covers all physical work on the premises. The general contractor’s responsibility is to approve contracts, keep the project within budget, and inspect the work.

Subcontracting is not limited to the construction industry; it is also used in other sectors. For instance, in trucking companies, subcontractors may be called in when specific types of trucks are needed, or there are not enough drivers to cover all routes. This type of subcontracting can be permanent, as needed, or done on a one-time basis, depending on the needs of both the company and subcontractor.

Manufacturers in various industries, such as computer and automobile manufacturing, often use subcontractors to supply parts. For example, in automobile manufacturing, the engine may come from one company, and the transmission from another, both assembled at the manufacturing facility.

Subcontracting is also important for manufacturers making a number of products from complex components. Computer manufacturers and automobile manufacturers often use subcontractors to supply parts. In an automobile, the engine may come from one company, and the transmission from another. They are then put together in a complete package at the manufacturing facility.

Subcontracting offers a number of advantages. First, it allows work on more than one phase of the project to be done at once, often leading to a quicker completion. Second, because subcontractors already have the expertise and equipment to provide the service, it is often much cheaper for them to do so than for a general contractor to acquire those skills and equipment. Finally, the subcontractor is usually able to work with a general contractor on more than one project, thus creating savings for both in the long run as a relationship is formed.

How many types of Subcontracting procedure in the Microsoft Dynamics NAV/Navision?

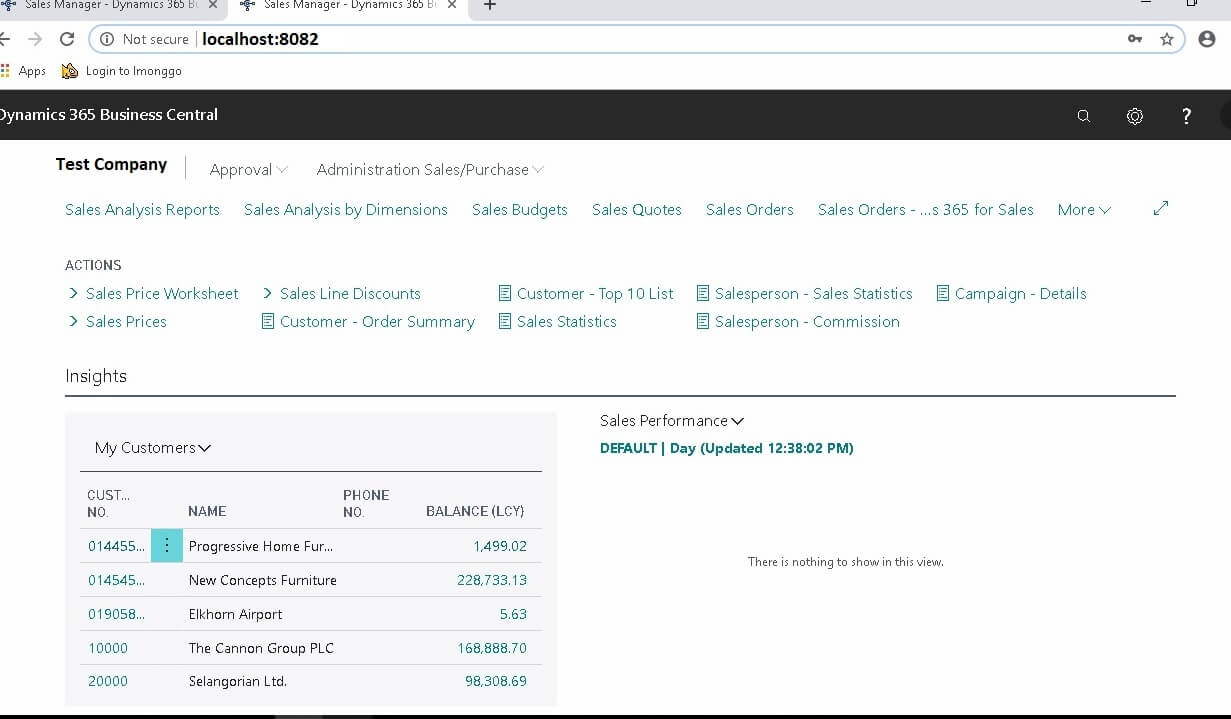

Microsoft Dynamics NAV / Business Central has mainly 2 types of subcontracting Orders handling

- 1.) Subcontracting Order given to the out side company

- 2.) Other company given Subcontracting to Us

Continue reading and understand SUBCONTRACTING IN NAVISION / Business Central.